Steps

-

Step 1

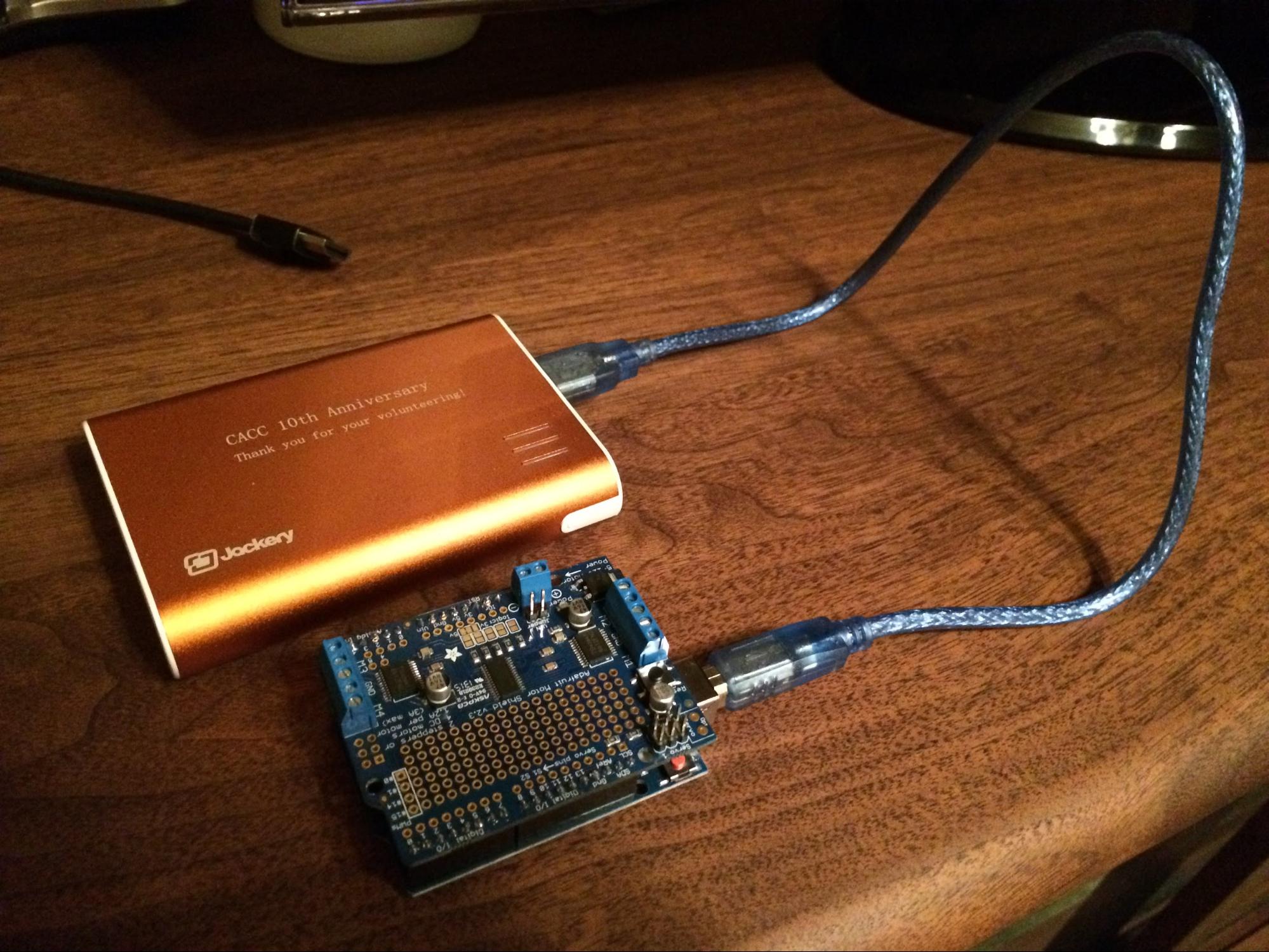

Setting Up Arduino

This pet feeder is Arduino compatible. Mikayla and I thought it was better for us to use Arduino to program it since it's an inexpensive and easy-to-program board. To set it up, all we had to was download the software, buy a board, and select the board in the port.

-

Step 2

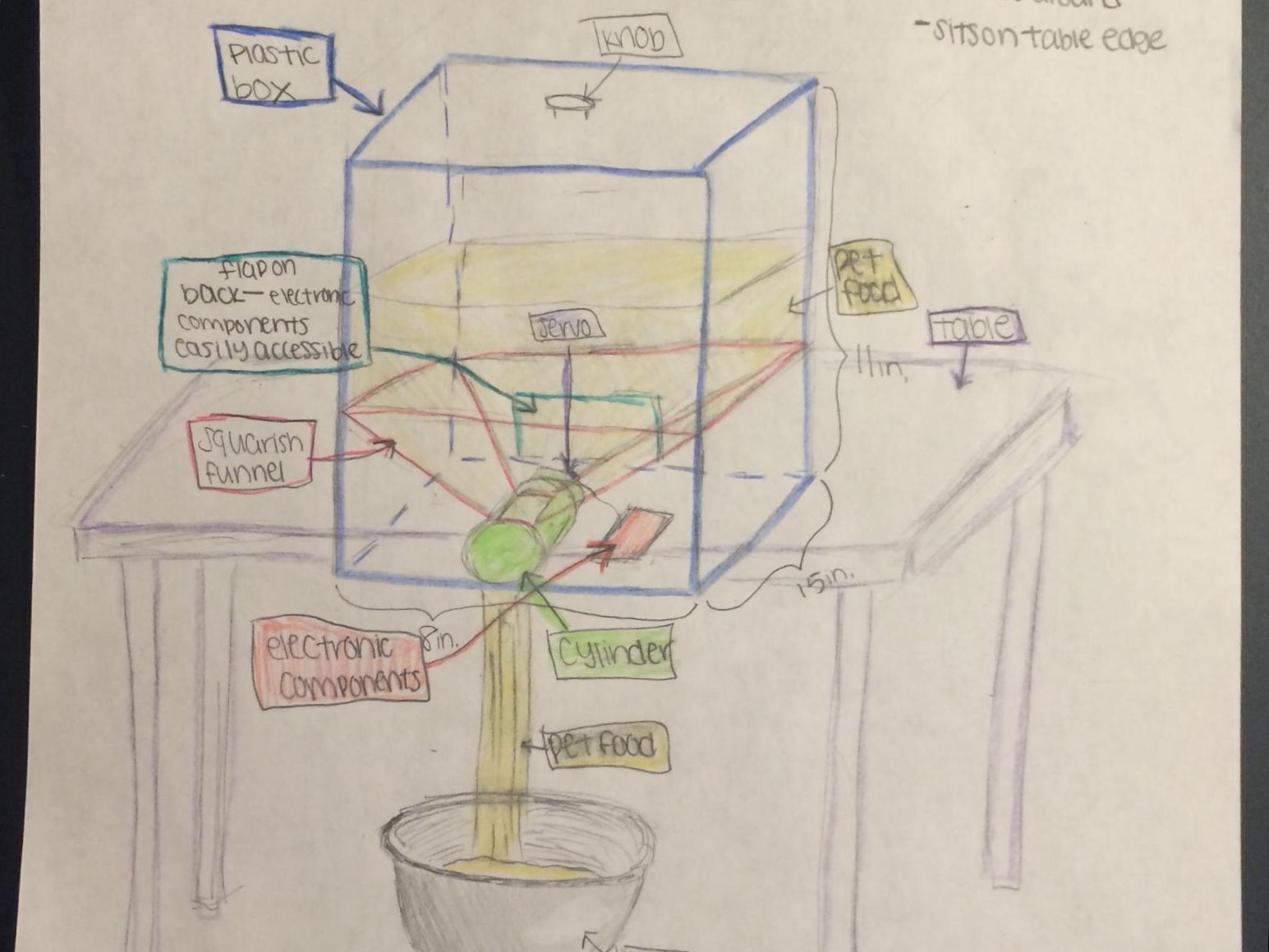

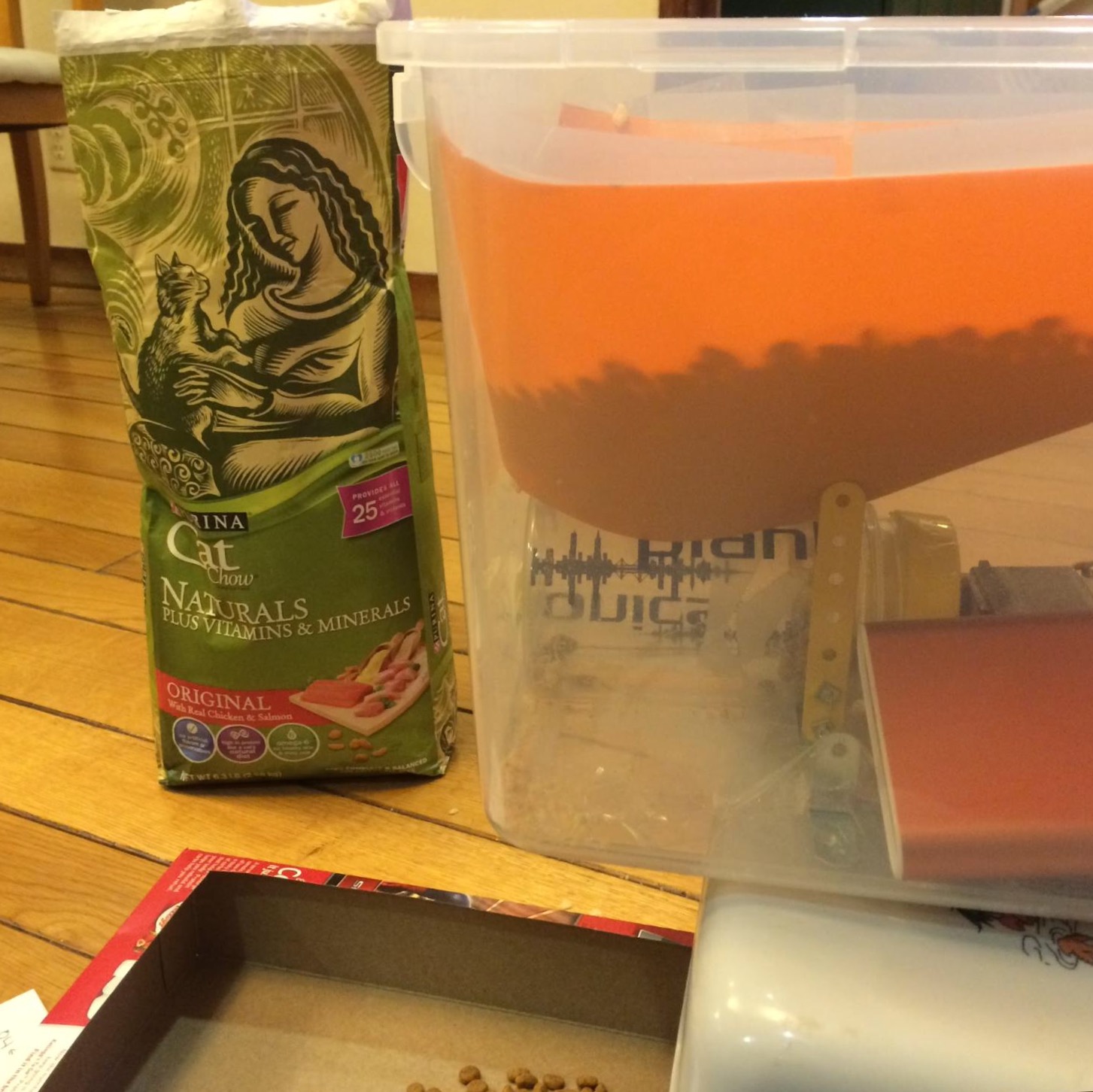

Making the Dispenser

The dispenser was made from a tapering water bottle. We cut it in half using a rotary blade and fit the small end into the big end. Then, we proceeded to cut out square-shaped holes. On the small half we cut one, and on the big half we cut two squares that were each on opposite sides. With this, a lid was superglued on the small end. The arduino was next. After programming it, we attached it on a motorshield with a servo, then attached that onto the dispenser lid. Whenever it turned, food would be dispensed.

-

Step 3

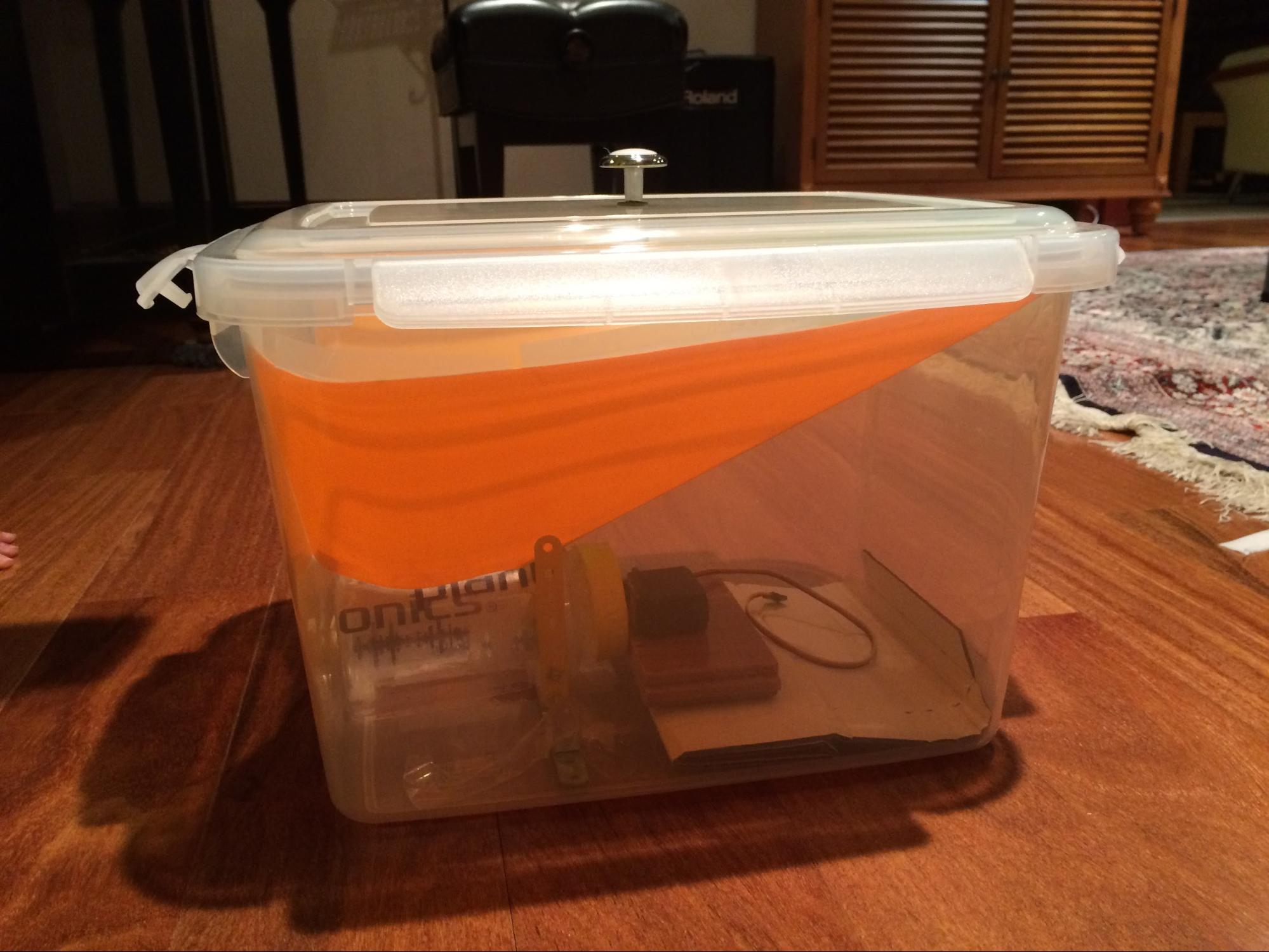

Building the Feeder

This part of the feeder stores all the food and creates an easy path for the food to fall down into the dispenser. We got a box (BPA-free, of course) and cut a square on the bottom that was the same size as the one on the dispenser. After, we put the dispenser into the box along with the arduino and chargable battery. On the back of the box we cut a small flap so the electrical componenets could be easily accessed. Four plastic sheets were carefully cut and placed along the four sides of the box, creating a slope in which the food could fall down.

-

Step 4

Testing

We wanted to test our feeder on two categories: timing and consistency. Since this was programmed with a computer, we all know for certain that the time will always be on the dot. However, the consistency part was different. There was a fill time, or the amount of milliseconds the cylinder had food falling into them. Then, the food dispensed. We measured the weight of the food to see if the weights were always consistent. Our design turned out successful -- the weights only differed at 0.2 oz at the most, which is barely anything. There were some notable discoveries, though. The less fill time there was, the less consistent weight was.