Steps

-

Step 1

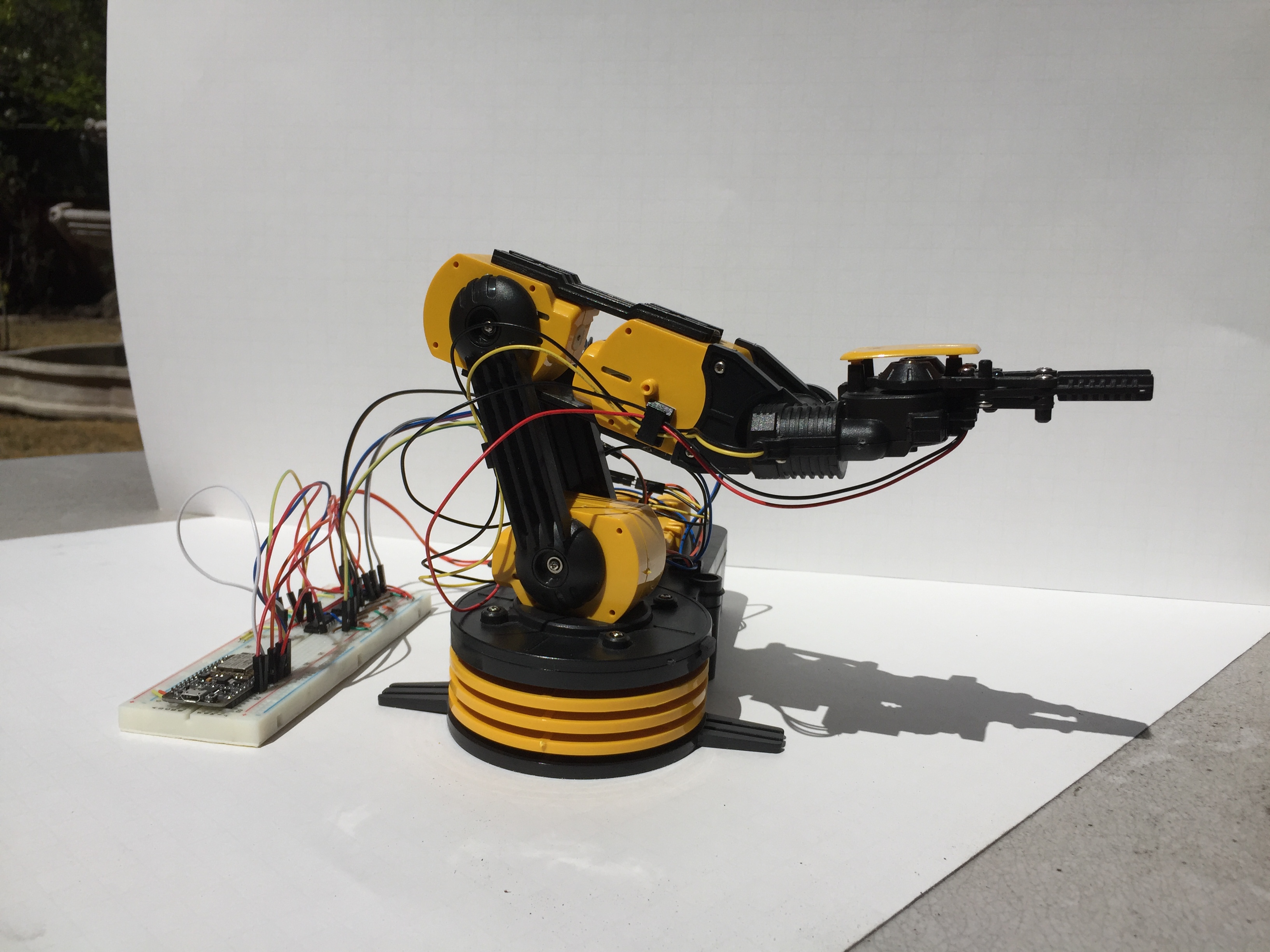

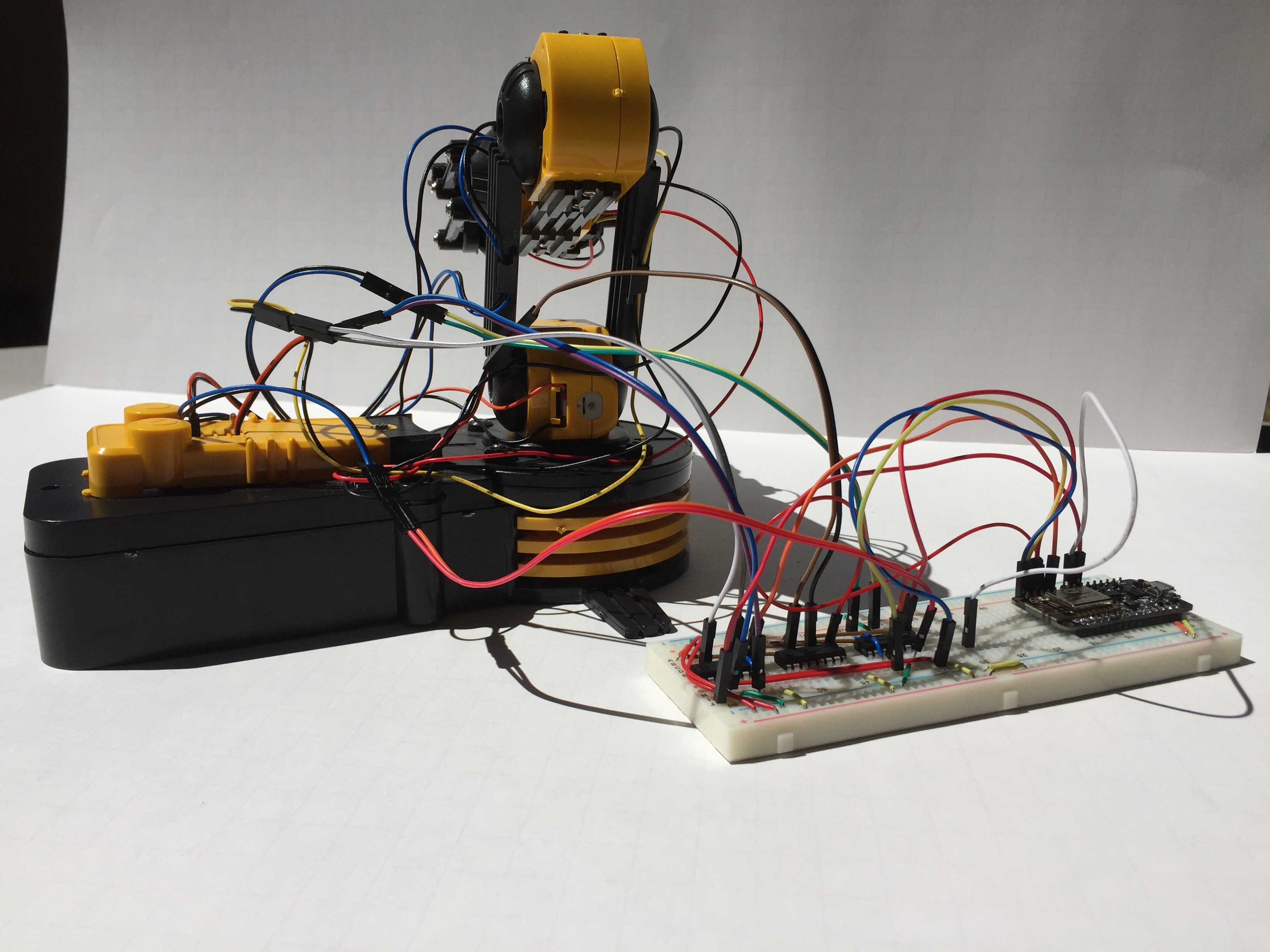

Modifying the Robot Arm

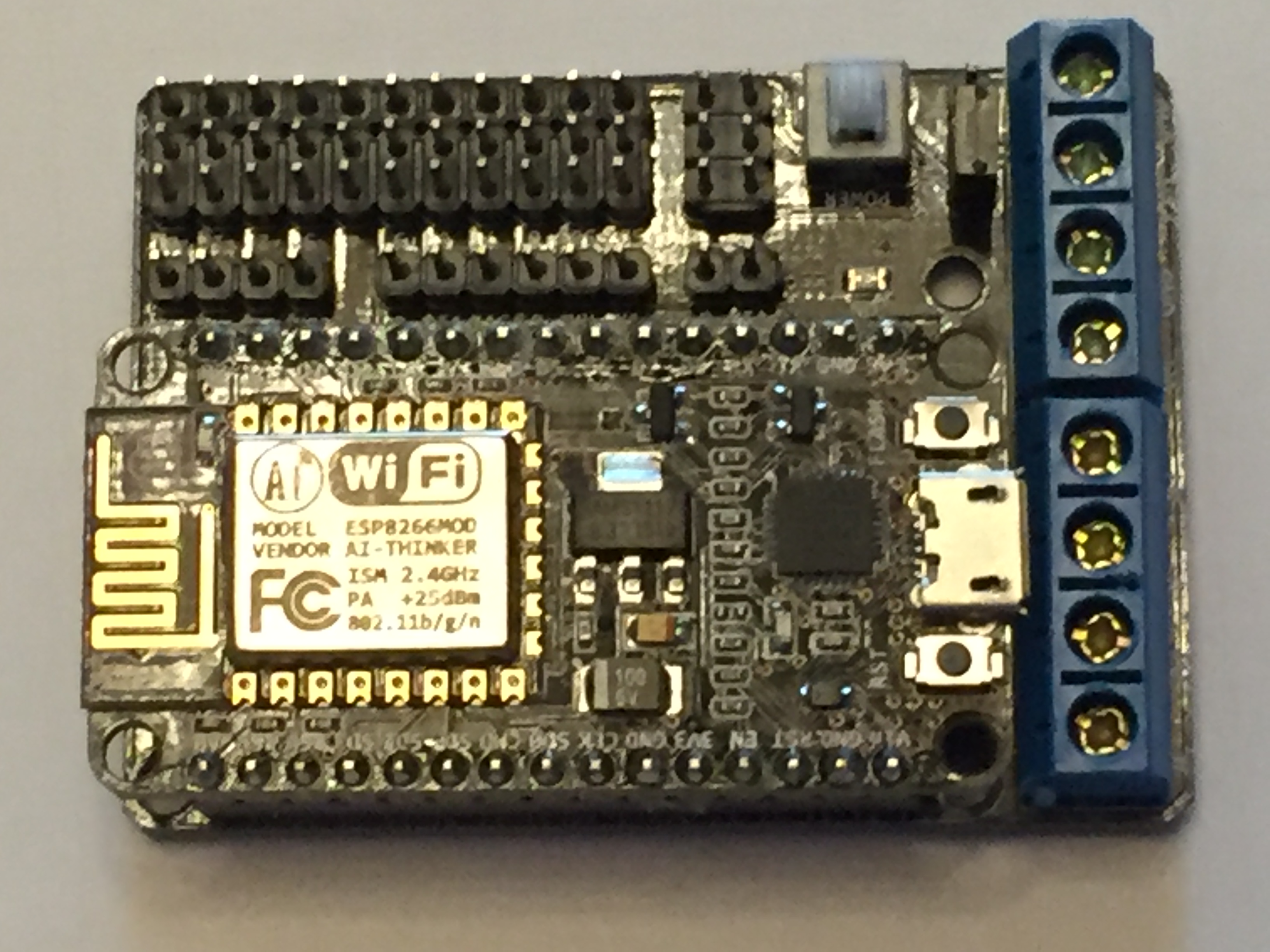

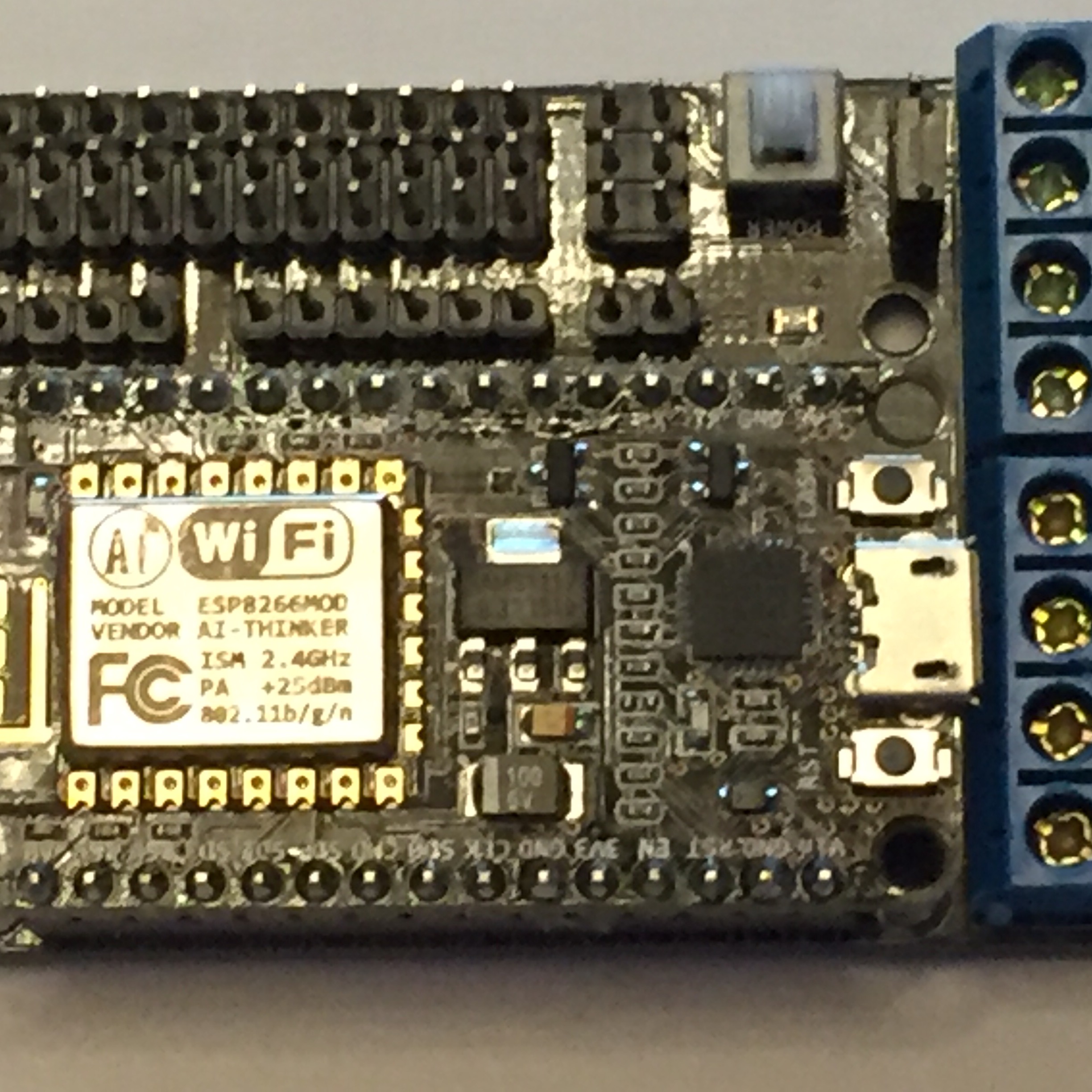

This robot arm was first mechanically controlled. To make it remote controlled, we replaced the original board with the NodeMCU board.

-

Step 2

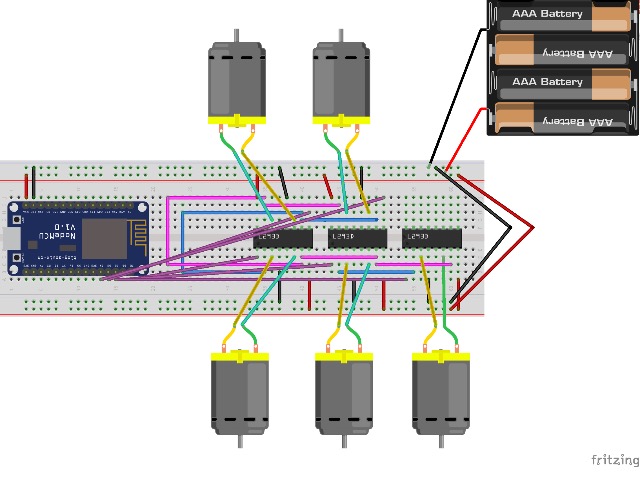

Wiring

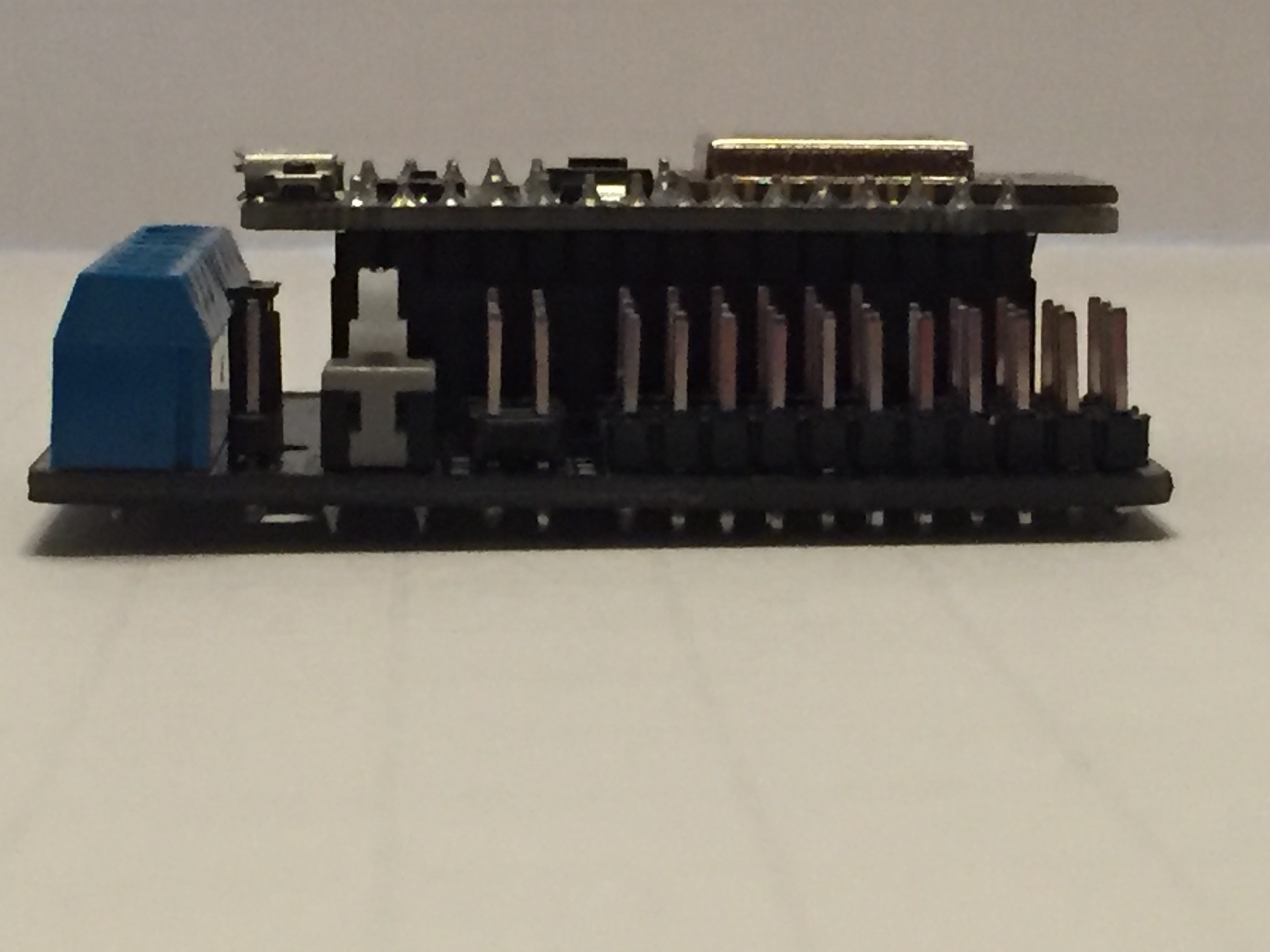

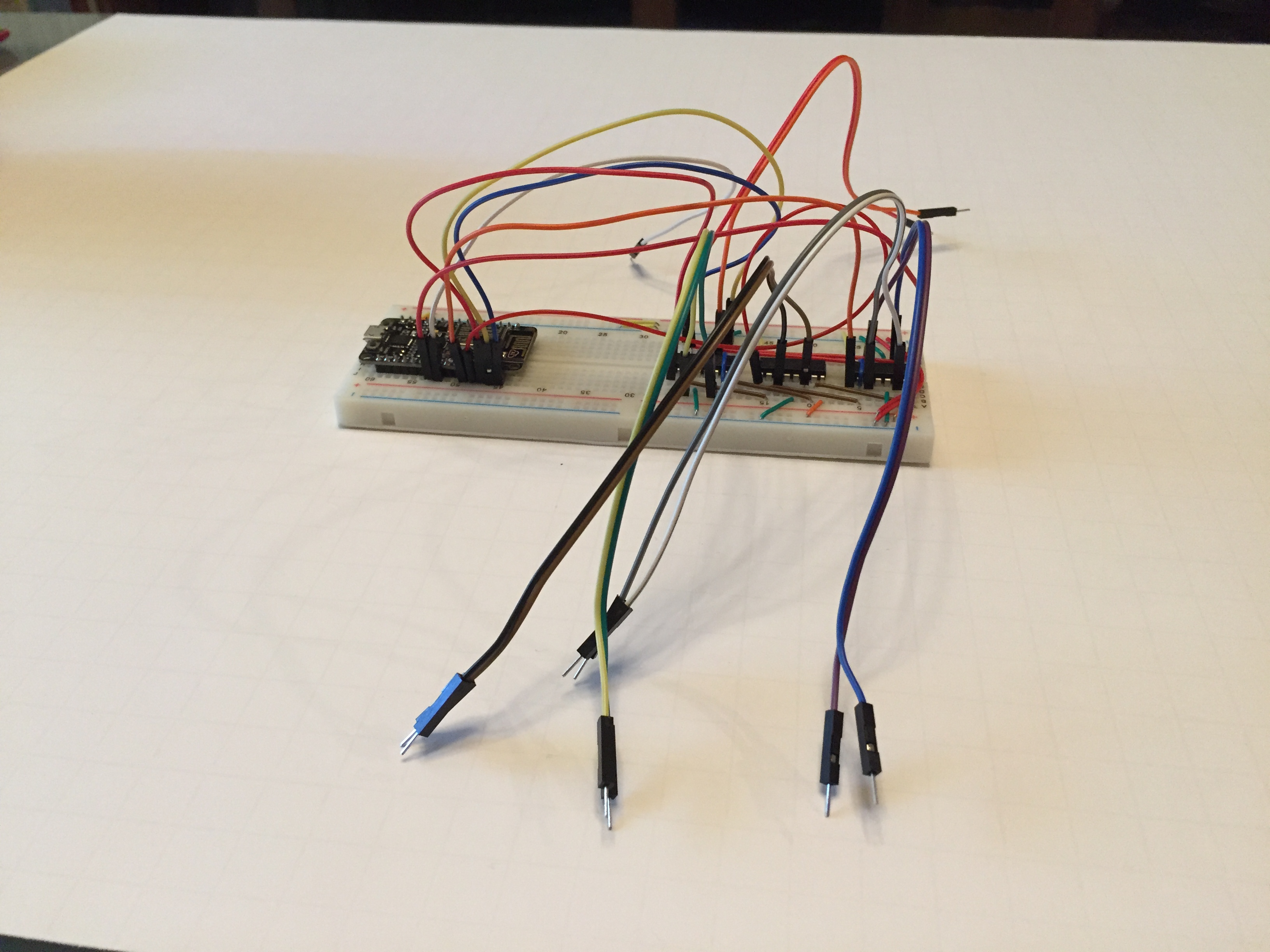

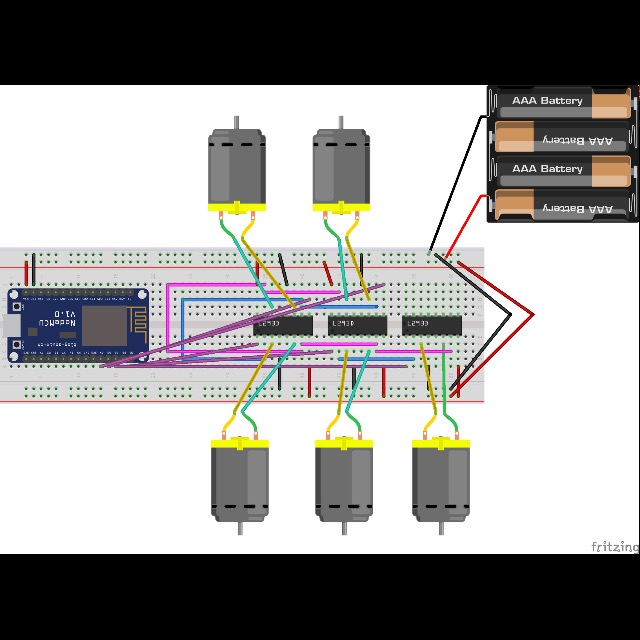

Initially, we used the motorshield to control the motors and hook up with the NodeMCU. After we figured out that didn't work, we used an IC chip called L293D. Each chip could control two motors, but there was a problem -- every motor needed three pins (a speed pin, input 1 pin, and input 2 pin). We had to control five motors for this project. As a result, fifteen pins had to be used! The NodeMCU clearly didn't have enough pins, so we needed another solution. A new wiring method was made. In the wiring method, two long bus wires were used to control all the input pins. This way, we only needed two pins instead of ten pins to control the inputs.

-

Step 3

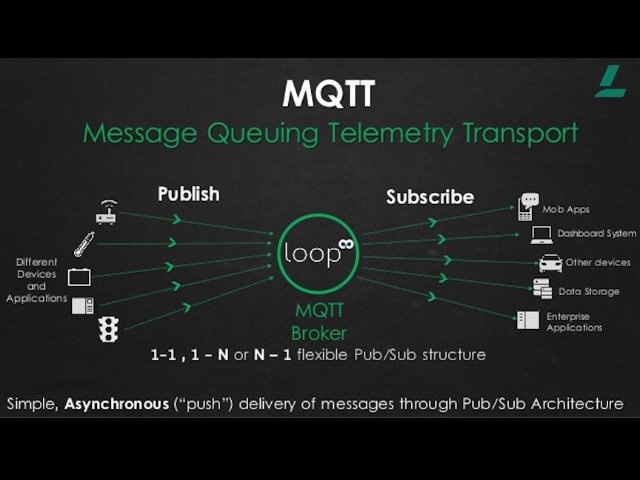

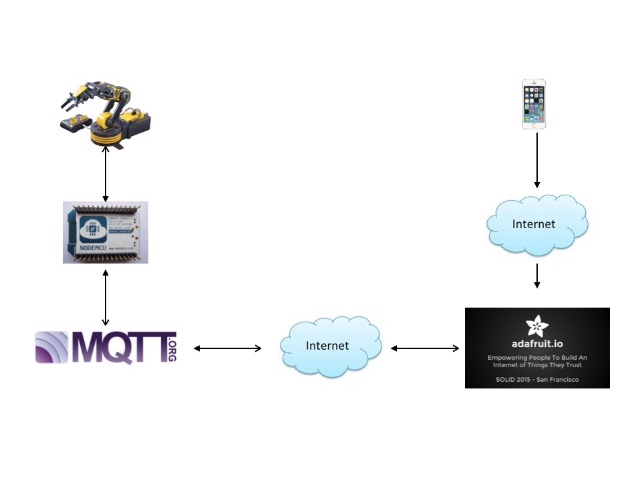

MQTT Integration

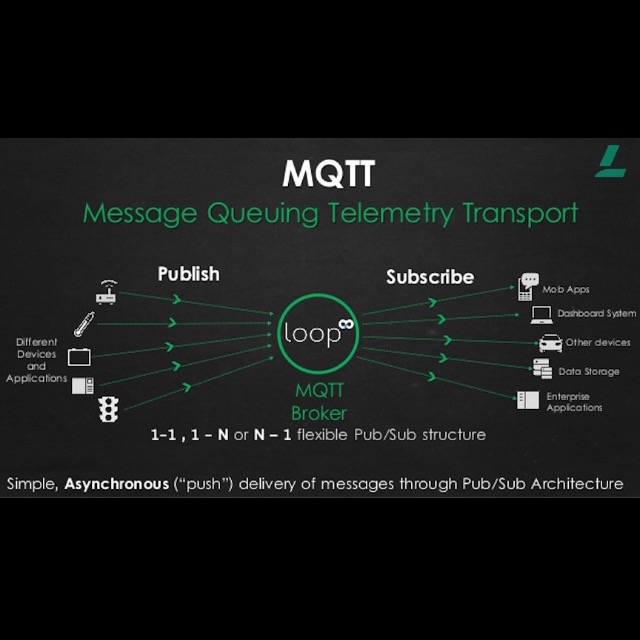

In order for the robot arm to be managed over wifi, we have to include a system called MQTT. MQTT has three parts -- the MQTT itself, a publisher, and a subscriber. The publisher puts out a message into the MQTT system, and whoever is registered to the right channel (subsciber) receives the message. For the robot arm, Adafruit IO's dashboard sliders are the publisher. We publish a mode for a certain joint (ex. wrist, -1). This is sent to the MQTT, then to the subscriber. The NodeMCU in the robot arm is the MQTT subscriber in this project.